Defense R&D Outlook: Additive Manufacturing

In November 2016, when the Department of Defense (DOD) released its first Additive Manufacturing Roadmap, the document began with a sentence that has proven to be something of an understatement: “Additive manufacturing (AM), which includes the commonly used term ‘3D printing,’ is a rapidly growing and changing discipline.”

It’s been less than three years since then. While much of the world continues to think of AM technology as a convenient way to make sturdy plastic objects from 3D printers, military personnel at all levels have been pushing its limits far beyond what most imagined possible.

At the Oak Ridge National Laboratory, the Disruptive Technologies Laboratory of the Naval Surface Warfare Center produced the military’s first 3D-printed submarine hull, a 30-foot submersible hull inspired by the SEAL Delivery Vehicle. Compared to a traditional SEAL submarine hull, which costs up to $800,000 and takes three to five months to manufacture, the six carbon-fiber sections of the new prototype were built in four weeks and assembled at a cost of $60,000.

At the Picatinny Arsenal in New Jersey, at the facility now known as the Combat Capabilities Development Command (CCDC) Armaments Center, the Army unveiled a grenade launcher, the Rapid Additively Manufactured Ballistics Ordnance (RAMBO), a modified version of the older M203 launcher. RAMBO consists of 50 separate parts, each of which, except for the springs and fasteners, was built through an additive manufacturing process. The materials used for these parts include plastic, aluminum, and 4340 alloy steel.

Maintainers at Hill Air Force Base in Utah installed a 3D-printed bracket, made of titanium, on an operational F-22 Raptor. The corrosion-resistant part was used to replace an aluminum bracket in the kick panel of the aircraft cockpit. It was the Air Force’s first operational use of a metallic 3D-printed part on an F-22, and happened just months after the service’s Rapid Sustainment Office installed 17 printed parts, including both polymer and metal components, on a C-5 Super Galaxy aircraft.

With the use of a gantry-mounted concrete printer jointly developed by the Army’s Engineer Research and Development Center (ERDC), NASA, and Caterpillar, Marines, soldiers, and Navy Seabees built a 500-square-foot hardened living space – a barracks – in just 40 hours at ERDC’s Construction Engineering Research Laboratory in Champaign, Illinois. The printer is a joint Marines/Army initiative known as Automated Construction of Expeditionary Structures, or ACES. Months later, the 1st Marine Logistics group, with the help of the Marine Corps Systems Command, the Army Corps of Engineers, and Navy Seabees, used the ACES printer to build a functional concrete footbridge in 14 hours, the first 3D-printed bridge in the western hemisphere, at Camp Pendleton, California. At the Institute for Soldier Nanotechnologies at the Massachusetts Institute of Technology (MIT), a research team supported by the National Science Foundation and the Office of Naval Research used additive manufacturing to produce soft, pliable nanostructures that can be manipulated when magnetized. The 3D-printed nanobots, which can be made to roll, crawl, jump, and grab, may someday be used as magnetically controlled biomedical devices.

Few technologies are as vigorously hyped throughout the military as additive manufacturing, for good reason: The ability to produce components on demand, at the point of need, will transform logistics, reduce material waste, and enable customization, all at a fraction of the costs and times involved in the manufacturing process that traditionally feeds military resupply and acquisitions.

AM is already being viewed as a possible alternative means of tackling problems unsolved by current budget levels: In the spring of 2019, the Navy’s Information Warfare Research Project Consortium issued a solicitation asking industry to use AM and innovative technologies to develop the Marines’ next amphibious transport, an item that was zeroed out of the most recent defense appropriation.

Such possibilities have serious implications for defense manufacturing: New designs can be prototyped and tested rapidly, without having to stand up production lines or create expensive tooling. In the future it may be possible for warfighters at forward outposts to print their own weapons, critical replacement parts, or even living quarters – but we’re not there yet. There are still a few hurdles to clear, both technical and organizational.

The Technology

The term “additive manufacturing” is used to distinguish the technology from more traditional “subtractive” methods, which form objects by cutting away from a piece of raw material and tooling it to achieve a finished product. While there are now several different types of AM, each forms an object in the same basic way: A programmed machine adds material, layer by layer, until a three-dimensional object is formed. The first 3D printing machines, produced in the 1980s, created objects out of thermoset polymers. Today’s machines can infuse these polymers with materials such as Kevlar, carbon fiber, and fiberglass, and also print objects made from a variety of materials including metals, ceramics, paper, food, and even living cells, introducing the possibility of printing human organs for transplant.

Initiatives such as the ACES program, which involves three military branches, NASA, and a private company, illustrate how the DOD achieves technical advances through collaboration. Innovations are made all the time by operational components such as the CCDC Armament Center, which owns more than 25 3D printers, including five contained within the mobile R-FAB system, a 3D printing lab in a shipping container. The R-FAB was recently deployed to U.S. Army Garrison Humphreys in South Korea, where machines have been used to print a number of replacement parts, mines, and mortar shells.

While these innovations are happening throughout the Defense Department, they are often nurtured by the military’s foundational research programs in additive manufacturing, conducted at the service branch corporate research laboratories – the CCDC Army Research Laboratory (ARL), the Naval Research Laboratory (NRL), and the Air Force Research Laboratory (AFRL) – often in collaboration with other service elements.

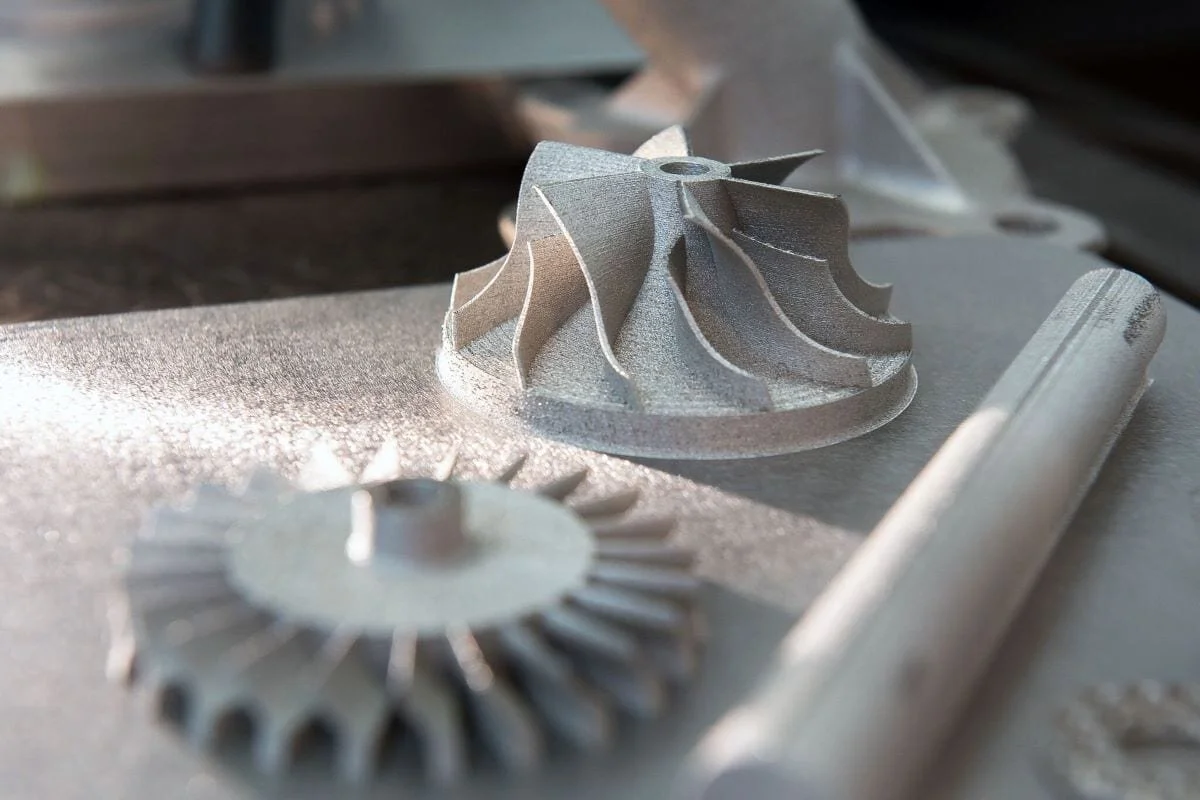

Titanium parts printed from powder and a laser provide researchers with high-strength, heat-resistant examples of the future of additive manufacturing.

Much of this foundational research takes the form of exploring new materials, but as Dr. Joseph South, who leads the ARL’s AM-focused Essential Research Program, pointed out, it also involves investigating ways a process can be altered in order to produce different material characteristics. For example, by controlling the processing parameters in a laser powder bed fusion machine (LPBF) – a 3D printer that uses metal powder to build objects – a user can modulate the laser power and scan strategy to control the microstructure, and thus the strength and hardness, of the printed object. Team members in ARL’s Manufacturing Science and Technology Branch recently used a LPBF to produce an impeller fan used in the powertrain of an M1 Abrams tank. “That impeller was operating in an erosive environment,” said South. “As it spun at high speed, it sucked in sand, which wore away the blades. If I can control my process parameters, I could make the surface harder. That part would last longer in operation.” The new part may someday be printed in the field, or as needed, rather than loaded onto a truckload of spare parts adding to the logistical tail of an expeditionary force.

All of the service branches are working to develop a process for printing explosives, propellants, and pyrotechnics, which aren’t currently approved for AM applications. Impressive as the Army’s RAMBO grenade launcher is, the machines that printed it can’t simply extrude explosive material through a nozzle. Explosive powder in a binder can be 3D printed, but an inert binder often dampens the powder’s explosive force. “Obviously we like to have things go boom,” said South. “And if we can have more boom, the better. We’re leveraging our in-house polymer science and our explosive formulation expertise to start making the binder energetic – not just an inert binder, but energetic particles integrated into it, trying to make the binder itself have energetic content.”

It doesn’t take a lot of imagination to see how this application could go wrong, which is why a major focus for ARL and the other corporate laboratories is design science, the development of tools to guarantee each build meets specifications. “We already have the capability now, numerically, using these design tools, to say that if we build a propulsion system in a certain way, this is what the result will be in terms of performance. The next step is to experimentally validate the numerical tools.”

Marines from I Marine Expeditionary Force learn how to operate the world’s largest concrete 3D printer as it constructs a 500-square-foot barracks hut at the U.S. Army Engineer Research and Development Center in Champaign, Illinois

Scaling Up, Scaling Out

Printing of a legacy part out of steel is certainly a milestone, and such technical innovations often grab headlines. But these breakthroughs themselves aren’t what will transform military logistics. The Navy isn’t cranking out printed submarines, and the Marines aren’t printing living quarters overseas – yet. There’s work to be done before such inventions can be manufactured by warfighters where and when they’re needed. That work consists of scaling up – proving a prototype can be printed multiple times to the same specifications – and scaling out, to extend these new capabilities everywhere the military might need them. An important part of scaling out is simply making digital models widely available. For example, the CCDC Armament Center maintains a digital Repository of AM Parts for Tactical & Operational Readiness (RAPTOR), a searchable joint database for 3D models that allows users to download, upload, and comment on parts in the database.

A key feature of RAPTOR is that it links expeditionary personnel to engineers, who can oversee the process and qualify parts and assemblies – validate that the items perform correctly and will result in expected outcomes. For a plastic visor clip, this is important, but for a part that may determine the airworthiness of an aircraft or the seaworthiness of a naval vessel, it’s a life-and-death issue.

In July 2016, for the first time, a U.S. naval aircraft, a V-22 Osprey tilt-rotor, flew with a flight-critical part produced by additive manufacturing: a titanium link and fitting assembly used to fasten the engine nacelle to the wing. For the AM Integrated Product Team (IPT) of the Naval Air Systems Command (NAVAIR), led by Liz McMichael, this demonstration was just the beginning. “We deliberately tried to jump over a very high technical barrier,” McMichael said. One of the critiques often leveled by skeptics, she said, had been that even if AM for low-end components could be scaled out, the process would never work for flight-critical structural components. After the Osprey flew with the nacelle clip, McMichael gave a photo of it to the NAVAIR commander, a three-star admiral, with the caption: “Now what?”

For the next two years, McMichael and her team stood up processes to get AM components, both metal and polymer, approved for use on aircraft. “That was a good idea, but it was still too slow,” she said. “We were starting to make it a more sustainable process, but it still hadn’t been adopted across the organization.”

In March 2018, the team began a new process to support the Marine Corps’ aviation fleet and manage requests for aircraft parts. At the time, a number of Marine service depots had low-end commodity printers, and McMichael wasn’t sure they could be used to print parts for naval aircraft. The engineering and ordnance members of the IPT devised a color-coding scheme to differentiate between components that wouldn’t pose a safety risk if they failed (green) and those that were critical for airworthiness (blue). Once this sorting had been performed – a task more difficult than it sounds, McMichael said – the team worked to devise a replicable process and data package for producing these low-risk components.

That effort has led to a data repository of multiple F/A-18 parts approved for manufacture as “green-box” components that can be made on an inexpensive polymer printer. “That starts to nibble on the next phase for this,” McMichael said, “which is scaling out, coming up with a process that can be used across the organization, across multiple communities – our vendors, our foreign partners, the rest of DOD, and big OEMs [original equipment manufacturers].”

NAVAIR is in the middle of this harder phase, McMichael said, and has begun to replicate this process across the naval aviation enterprise. More than 170 different AM parts have been approved for use in naval aircraft – close to 300, said McMichael, including parts produced for NAVAIR by OEMs. “We still do research and development work for AM,” said McMichael. “But we’re also operationalizing. At this point, we have fleet guys who have printers who are making their own parts using additive and putting them on airplanes.”

The RAMBO grenade launcher. The 50 separate parts that makeup RAMBO, except springs and fasteners, are 3D printed

In a blend of pop culture showmanship and high tech, the U.S. Army has revealed a grenade launcher made almost entirely from 3D-printed parts. Even better, it fires 3D-printed grenades. The project highlights the Army's interest in integrating new manufacturing technologies, ideally lowering costs and easing supply demands down the road. Rapid Additively Manufactured Ballistics Ordnance, or R.A.M.B.O., is a modified M203 grenade launcher with a shoulder stock and pistol grip. The M203 grenade launcher is an older, pump-action design that was fitted under the barrel of an M16 rifle or M4 carbine. It's also probably no longer protected by patent. R.A.M.B.O. consists of 50 individual parts, and all of them with the exception of springs and fasteners were made by 3D printing. The barrel and receiver were made of aluminum using direct metal laser sintering, which the U.S. Army's Acquisition Support Center describes as a " process that uses high-powered precision lasers to heat the particles of powder below their melting point, essentially welding the fine metal powder layer by layer until a finished object is formed". The trigger and firing pin were printed in 4340 steel. The grenade launcher barrel and receiver took about 70 hours to print and then required 5 hours of post-print finishing. The barrel was tumbled in an abrasive rock bath and then Type III hard-coat anodized to provide a rugged finish.

R.A.M.B.O.'s printed parts, minus the receiver and barrel.

The Army is impressed with the process, which proves that someone with uncommon 3D printing equipment can actually build durable grenade launcher parts. "The tooling and setup needed to make such intricate parts through conventional methods would take months and tens of thousands of dollars, and would require a machinist who has the esoteric machining expertise to manufacture things like the rifling on the barrel. The grenade launcher wasn't the only thing the Army 3D printed. Tt made grenades, too. The Army printed several M781 training rounds, which do not have explosives, out of aluminum and glass-filled nylon. The 3D printed grenade launcher and grenades were tested in October 2016 and displayed zero degradation after 15 shots. 3D printed grenades came within five percent of the muzzle velocity of regular production grenades, proving that the system was performing close to the real thing. Army engineers involved in the project hit just one snag during testing, one that was easily fixed. Early versions of the grenades experienced cracking in the aluminum cases. To fix, engineers simply went into the software and made the walls of the cartridge case thicker. The next grenade was printed with the thicker walls and the problem was solved. The production of actual, useful heavy weapons has serious implications for defense manufacturing. New designs can be quickly prototyped and tested without creating new, expensive tooling. Down the road, all weapons might someday be produced this way. And even further into the future, it could be possible for soldiers at forward outposts to print their own weapons or critical replacement parts.